Fender Apron

It was over a year before work started on the Mustang. This was going to be a simple modification and the car would be back on the road in no time.

BWAHAHAHAHA

The idea was to just replace the shock towers and put the car back together until the Cammer was built. Over time the sheet metal would be straightened out or replaced. With very little experience in body work, replacing is probably more in line with what will happen.

First step was to strip the front of the car to gain access to the towers. The hood and radiator were removed, followed by the engine and transmission.

Followed by the front suspension. The suspension hangs off of the shock towers so yeahhhhh, I’m gonna need those to go.

The removal process is always the fun part but what you find as the pieces start coming off can really put a damper on the enjoyment.

The bad news showed up when the fenders were removed.

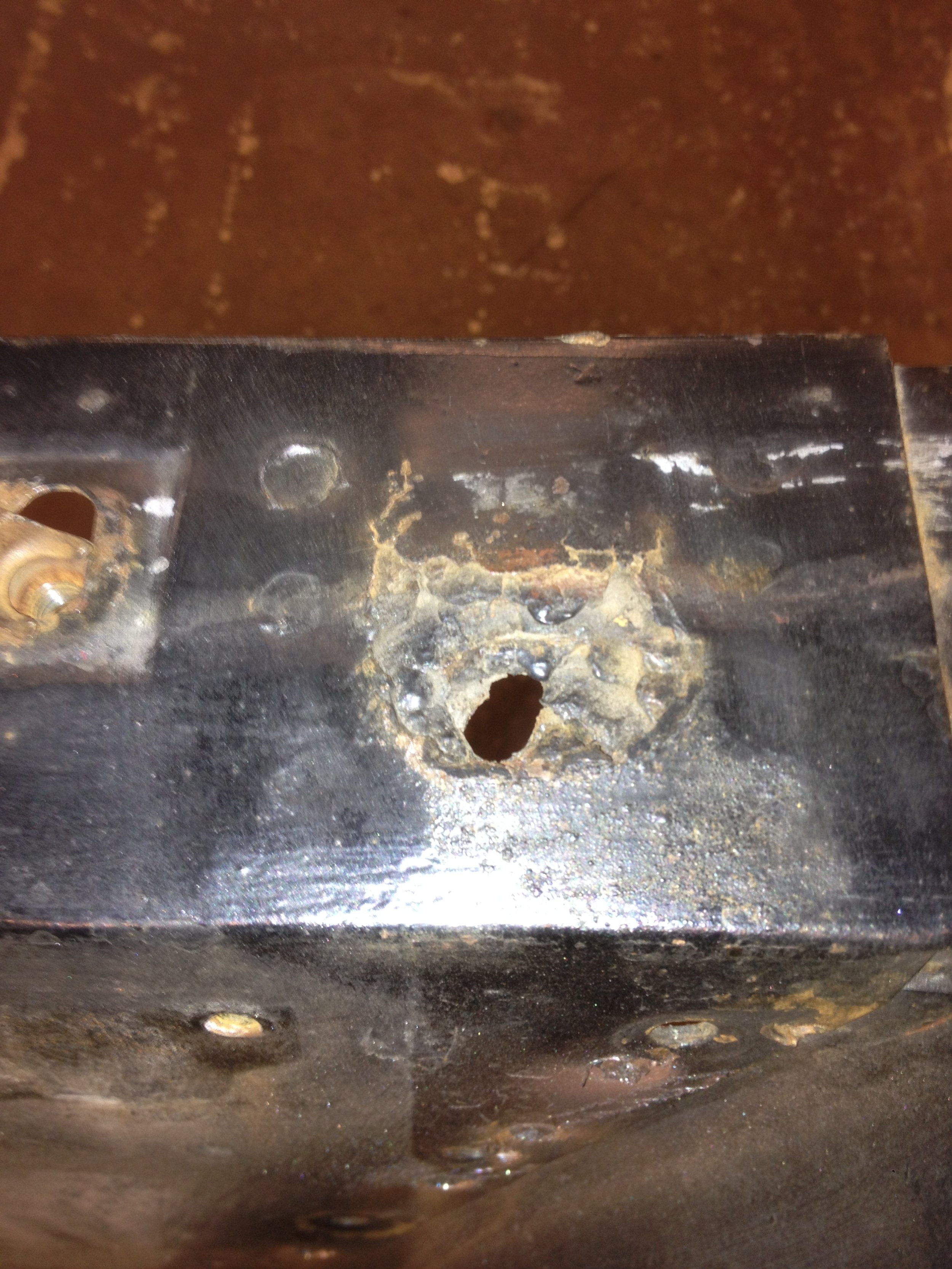

Where the fender apron overlap the shock tower top rail, you could see lumps forming. Of course I had to poke at them with a screw driver. The rust went all of the way through.

This wasn't going to go as quickly as earlier thought.

Further inspection revealed that the threaded inserts that hold the hood hinges to the rear apron were missing. Nuts and bolts were holding the hinges in place. The front right apron, the one where the battery tray is bolted to is the worst. The ledge that supports the battery tray looks odd. Looking underneath the ledge shows that it had been eaten away from rust and the hole was patched with fiberglass and resin.

The left front apron looked pretty good and I cannot remember why I decided to replace it. Maybe it was a case of guilt through association.

CJ Pony’s Dynacorn Apron Kit, 1969 Mustang

I had been studying a magazine article for a while that was about replacing the cracked shock towers on an earlier model Mustang so that was my guide. In that article, the author used the apron to locate the new towers once the old ones had been removed. That made sense. My plan of attack was sorted. Replace the apron before swapping the towers.

I found a neat little widget while walking through Harbor Freight. It was a self-contained tiny hole saw made to cut out spot welds. With that and my trusty Makita drill motor, there wasn’t a spot weld that was safe.

I worked on one fender section at a time. Remove the bad apron, replace it with new metal and move onto the next.